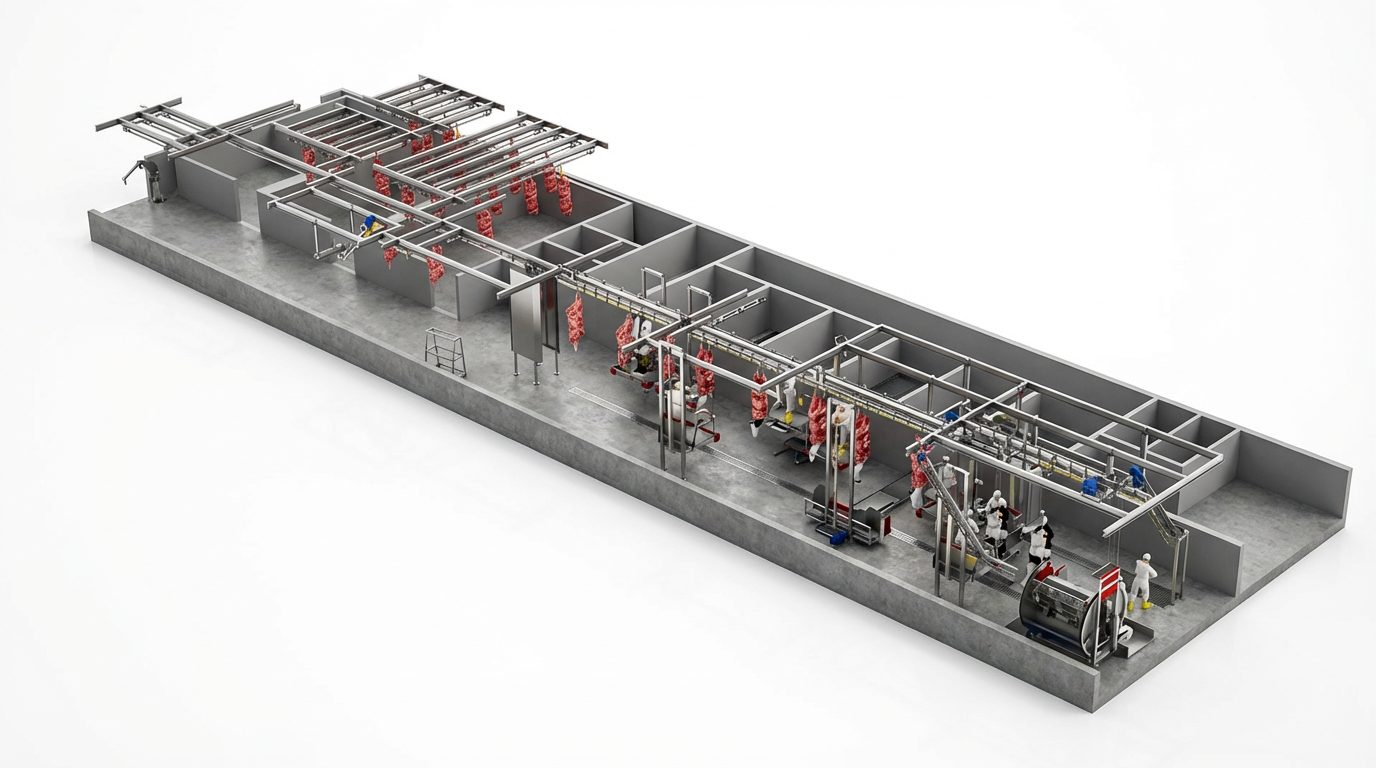

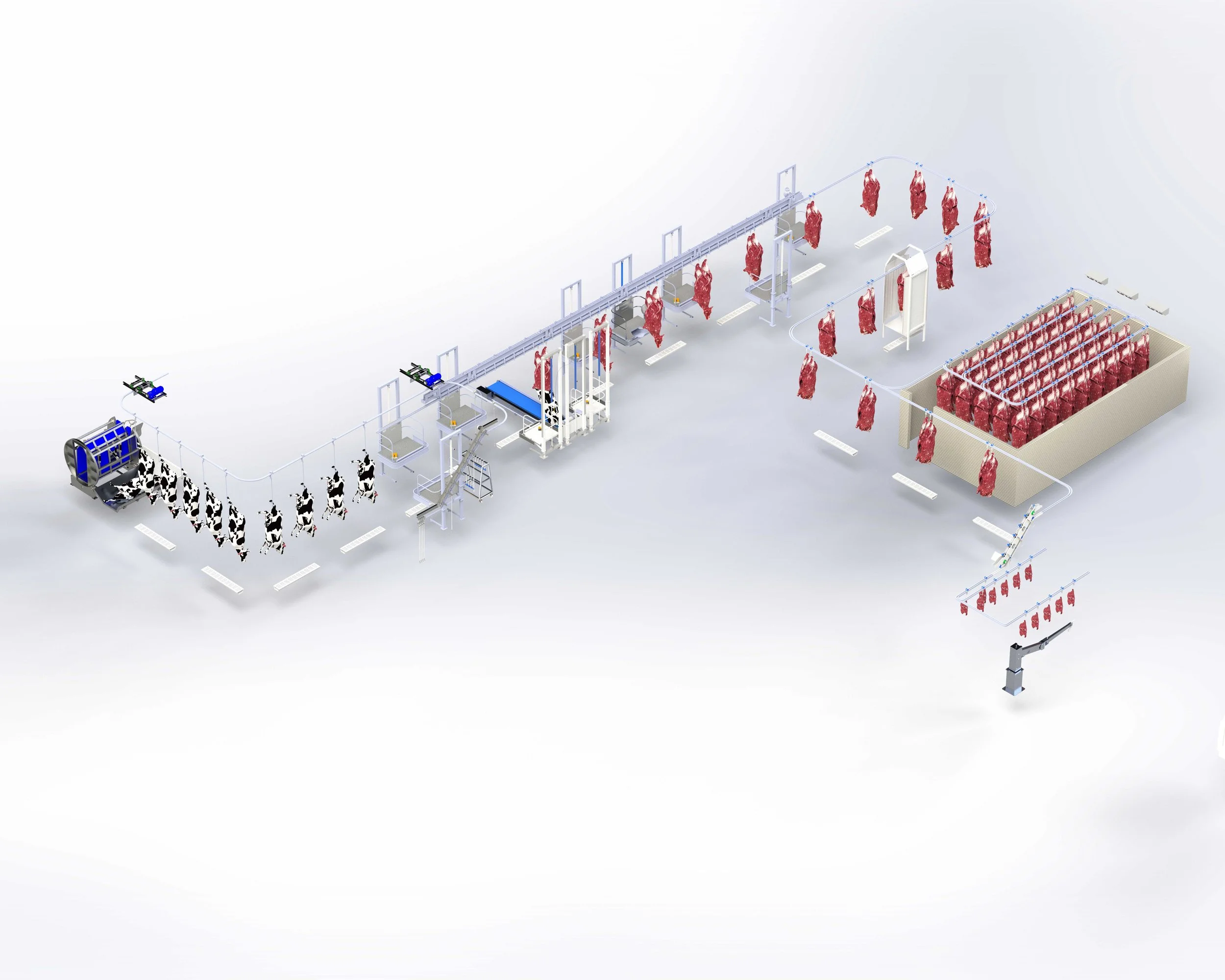

CATTLE SLAUGHTER SOLUTION

Turnkey Cattle, Beef, and Camel Slaughterhouse Facilities

Industrial Cattle Slaughterhouse Equipment & Turnkey Beef Abattoirs

"Teknotes Group designs and manufactures heavy-duty Cattle Slaughter Lines capable of processing up to 60-100 heads per hour.

From our Rotary Halal Killing Boxes to high-capacity Hydraulic Dehiders and Carcass Splitting Platforms, we provide complete turnkey solutions tailored for modern beef abattoirs. All equipment is built from AISI 304 Stainless Steel, ensuring hygiene, durability, and full compliance with Halal Ritual Slaughter standards."

-

Rotationary Killing Box ,Classic Cutting Cabin, Bleeding Line, Bleeding Conveyor,Return Hook Line and Helix, Bleeding Hooks, Elevator, Hoist, Butcher Platforms, Bleeding Pan, Transfer Units,

-

Processing Line, Processing Conveyor, Platforms, Hoist , Elevator, Skin Dehider Machine, Carcass Splitting, Saw Tools, Processing Hooks, Shower Cabin, Leg Spreader,

-

Cleaning Pan, Chutes, Offal Trolley, Offal Hanger, Liver Conveyor, Tripe Cleaning Machine, Bowel Cleaning Machine, Omasum Cleaning, Tripe Waste Pump,

-

Corridor, Cold Room Twinrail Line, Pre Cooling Conveyor, Hooks,Overhead Scale,

-

Carcass Loaiding Arm,

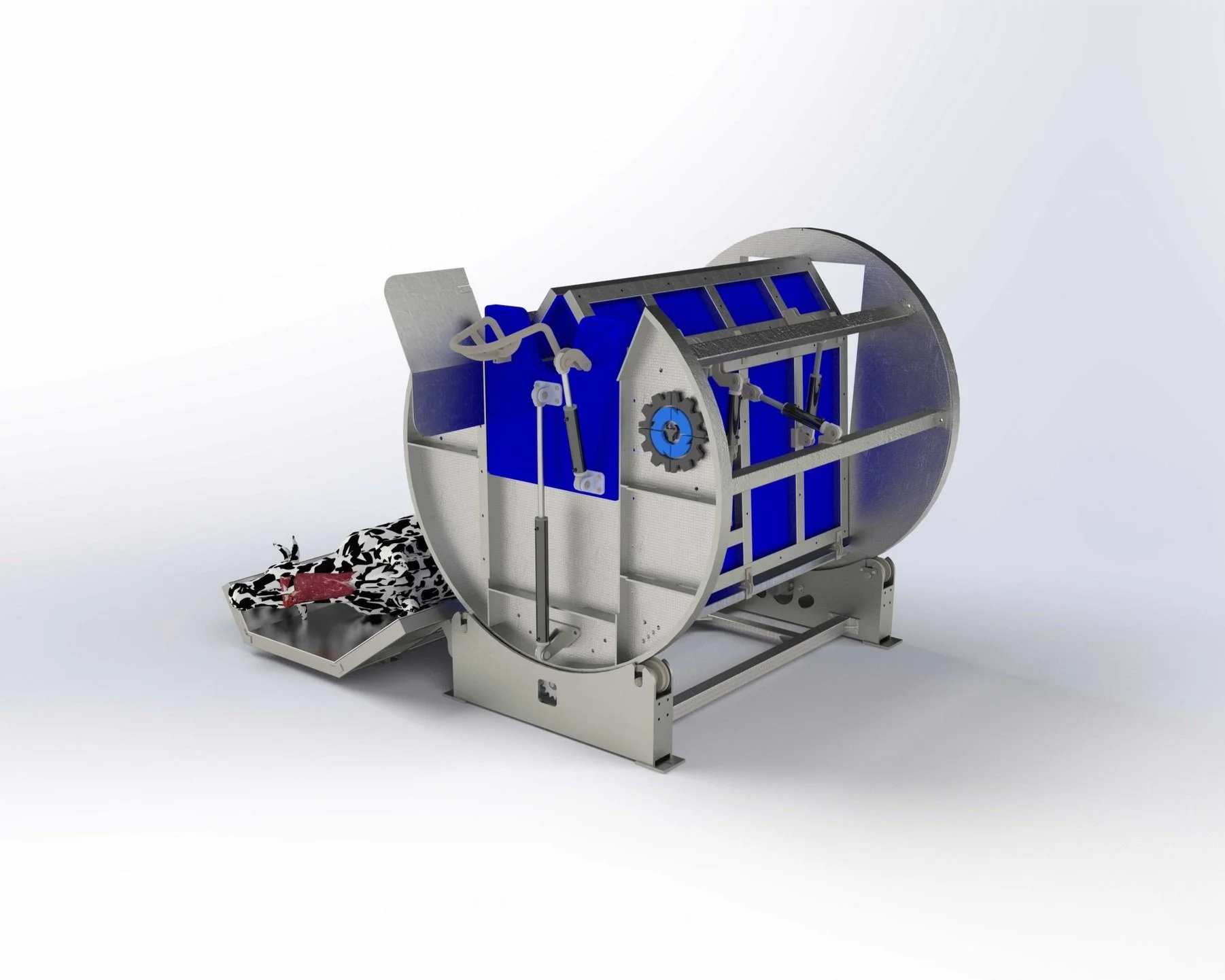

Rotary Halal Cattle Killing Box | Hydraulic & Pneumatic Ritual Slaughter System

Maximize Efficiency and Animal Welfare with Teknotes Rotary Killing Box

Designed for high-capacity modern abattoirs, our Rotary Halal Cattle Killing Box ensures fully compliant ritual slaughtering. Engineered with advanced hydraulic (or pneumatic) systems, this unit provides 180-degree rotation to position the animal safely and calmly for the cut.

Features:

Halal & Kosher Compliant: Perfect head restraint system for precise ritual slaughter.

Heavy-Duty Construction: Manufactured from AISI 304 Stainless Steel or hot-dip galvanized steel for maximum durability.

Safety First: Designed to protect the operator while ensuring low stress for the animal (Animal Welfare compliant).

High Throughput: Rapid cycle time allows for processing up to 40-60 cattle per hour (depending on the model).

Technical Specs

Operation System: Hydraulic / Pneumatic

Rotation: 90° / 180° Full Rotation

Material: AISI 304 Stainless Steel (Food Grade)

Engine Power: 4 kW / 5.2 hp

Capacity: Up to 1000 kg Live Weight

Dimensions: 2000mm (L) x 2600mm (W) x 2500mm (H)

Rotary Halal Killing Box & Cattle Casting Pen "Ensure precise ritual slaughter with our advanced Rotary Halal Killing Box. Designed for modern abattoirs, this hydraulic cattle casting pen features 180° rotation for full animal welfare compliance and operator safety. Built from heavy-duty stainless steel, it guarantees high efficiency for Halal and Kosher meat production."

100% Halal Compliance & Certification

At Teknotes Group, we understand the sanctity of Halal production. Our slaughterhouse systems are engineered in strict accordance with Islamic Slaughtering Principles and animal welfare regulations.

Especially our Rotary Killing Boxes are designed to ensure the animal faces the Qibla efficiently, allowing for a precise and humane ritual cut without causing unnecessary stress to the animal.

Ritual Compliance: Equipment design allows for proper positioning and bleeding. Animal Welfare: Low-stress handling systems compatible with Halal standards. Hygiene: Stainless steel surfaces ensuring "Tayyib" (Clean/Pure) processing.

-

🔹 Fully Automatic System

Designed specifically for Halal slaughtering, this system operates completely automatically to ensure maximum hygiene, efficiency, and animal welfare.

Ensures high productivity and humane handling with fully automatic Halal slaughter equipment — ideal for large-scale abattoirs. -

🔹 Pneumatic & Hydraulic System

Equipped with pneumatic and hydraulic pistons, this system securely restrains the animal from both sides and the top, ensuring complete stability during slaughtering.

Designed for maximum safety, animal welfare, and operational efficiency, providing reliable performance for modern Halal slaughterhouses. -

🔹 Cattle Halal Killing Box

A secure and hygienic cattle killing box designed in full compliance with Halal slaughtering standards.

Constructed from stainless steel, the system ensures operator safety, easy cleaning, and smooth rotation control for precise Halal cutting operations.

CLASSIC SLAUGHTER BOX

Galvanized Body or Stainless Steel

Pneumatic Cattle Killing Box & Ritual Trap

Halal Compliant Restraining System for Modern Beef Abattoirs

The Teknotes Pneumatic Cattle Killing Box (Classic Ritual Trap) is designed to restrain cattle of all sizes safely and humanely for the slaughter process.

Manufactured entirely from AISI 304 Quality Stainless Steel, this unit features a robust NPU 120 profile frame, ensuring stability against the heavy movements of large bulls. The system utilizes pneumatic cylinders to compress the animal from three sides, securing it perfectly for either Halal ritual slaughter or stunning, ensuring maximum operator safety and animal welfare compliance.

Universal Fit: Engineered to accommodate cattle of all sizes, from calves to heavy bulls, without adjustment.

Pneumatic Restraint (3-Way): Features collapsible sides powered by pneumatic cylinders to securely hold the animal, preventing thrashing and stress.

Halal Positioning Floor: Equipped with a movable floor mechanism designed specifically to facilitate proper positioning for the Halal cut.

Automatic Entry Gate: The front gate closes automatically upon animal entry, streamlining the flow and securing the trap instantly.

Heavy-Duty Construction: Built on a reinforced NPU 120 Stainless Steel Chassis for extreme durability and corrosion resistance in wet environments.

Waterproof Operation: Pneumatic system is designed for trouble-free operation in high-humidity and wash-down conditions.

-

🔹 Coating System

For maximum durability and long service life, the system can be manufactured either in stainless steel or with a hot-dip galvanized finish, ensuring hygiene, strength, and resistance in slaughterhouse environments.

-

🔹 Pneumatic System

Mounted securely to the floor, the structure is designed to be collapsible on three sides with pneumatic cylinders, providing operator safety, durability, and efficient operation under all abattoir conditions.

-

🔹 Suitable for Halal Slaughtering

Designed to meet international Halal standards, ensuring animal welfare, hygiene, and safe slaughterhouse performance for modern meat processing facilities.

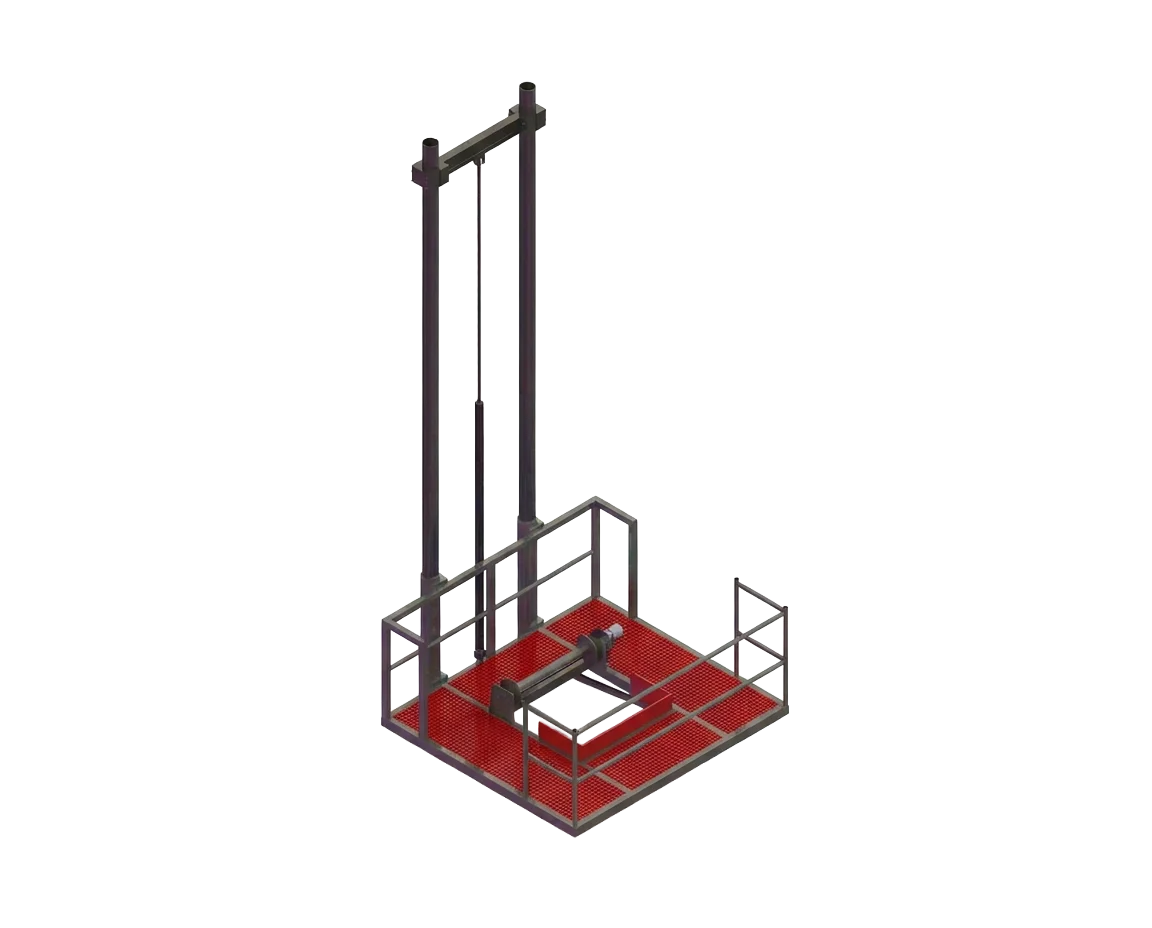

Cattle Bleeding & Transfer Hoist (Heavy-Duty Elevator)

Automatic Lifting System for Industrial Beef Abattoirs

The Teknotes Cattle Transfer Hoist is a heavy-duty lifting system designed to elevate cattle carcasses from the slaughter floor (or killing box) to the overhead bleeding conveyor.

Engineered for high-capacity slaughterhouses, this robust elevator ensures the smooth and safe transfer of heavy bulls and camels (up to 1,500 kg). Powered by a high-torque 7.5 kW GearMotor, it synchronizes perfectly with the slaughter line, minimizing manual labor and ensuring strict compliance with occupational safety and hygiene standards.

High-Performance Power: Equipped with a powerful 7.5 kW GearMotor to lift heavy carcasses effortlessly and continuously.

Rigid Construction: Built with a reinforced Heavy-Duty NPU Profile Frame to withstand intense vibration and heavy loads without bending.

Jam-Free Operation: Features specially designed foldable joints to prevent chain obstruction, ensuring a smooth, uninterrupted lifting cycle.

Seamless Integration: Fully compatible with Teknotes Overhead Rail Systems, providing a direct link between the Killing Area and the Bleeding Line.

Safety Mechanisms: Includes emergency stop systems and load brakes to protect operators during the lifting process.

Hydraulic / Pneumatic Cattle Dehider & Hide Puller

High-Capacity Skinning Machine for Premium Leather Quality

The Teknotes Cattle Dehider Machine is a high-performance skinning unit designed to remove the hide from the carcass in a single, smooth vertical motion.

Unlike manual skinning, this Hydraulic Hide Puller winds the skin onto a stainless steel drum, pulling it downwards without damaging the subcutaneous fat or the leather grain. Powered by a robust Hydro-Motor, it ensures consistent peeling even on heavy bulls, maximizing the commercial value of the hide while maintaining strict hygiene standards with its full AISI 304 Stainless Steel construction.

High Throughput: Capable of processing 30–40 heads per hour, making it ideal for medium-to-large scale beef abattoirs.

Hydraulic Power: Driven by a high-torque Hydro-Motor to handle heavy hides effortlessly without stalling.

Smooth Vertical Travel: Features a precision Piston System (Hydraulic or Pneumatic) for controlled up-and-down movement, preventing jerky pulls.

Hygienic Drum System: The winding drum and chain mechanism are manufactured entirely from AISI 304 Stainless Steel to prevent contamination.

Operator Safety: Designed with shielded moving parts and emergency controls to ensure a safe working environment.

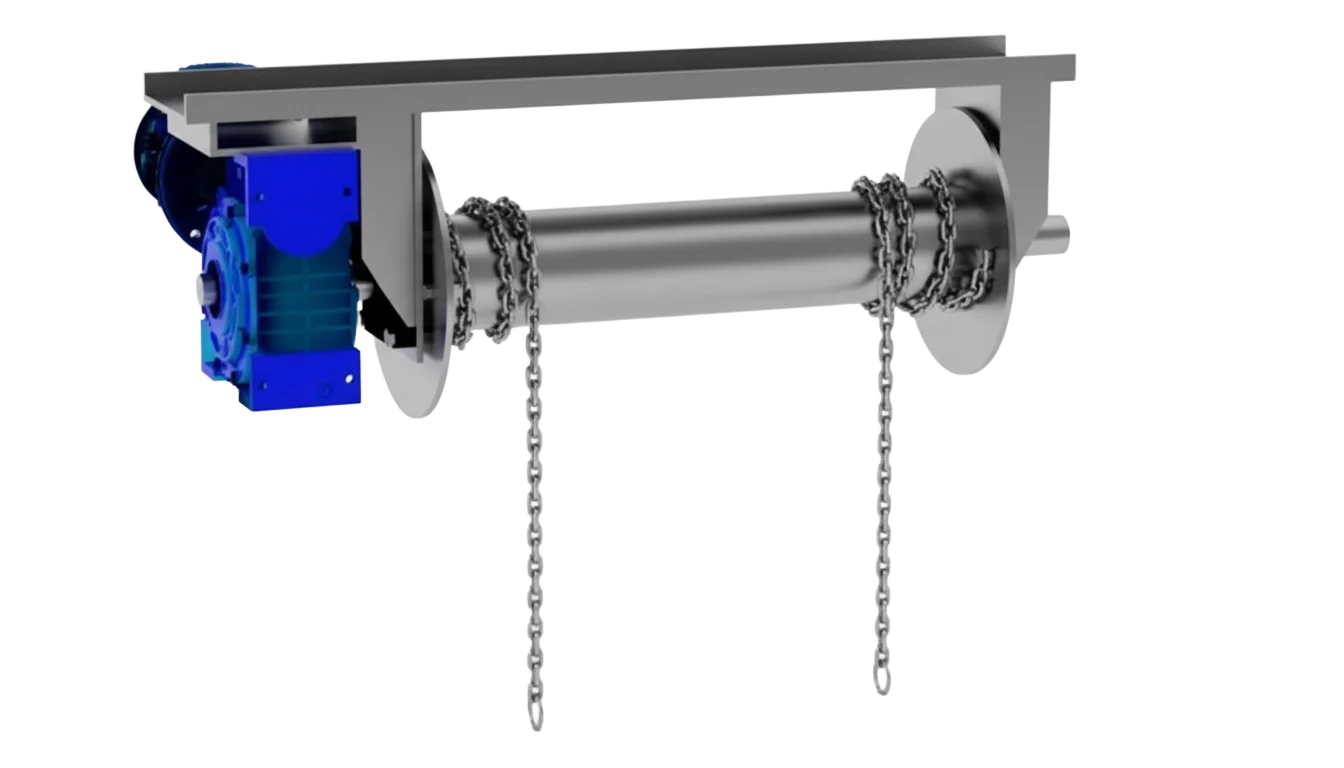

Mechanical Cattle Dehider Machine (Electric Drive)

The Teknotes Mechanical Dehider is a robust and reliable solution designed for slaughterhouses seeking high performance with low maintenance costs.

Unlike hydraulic systems, this unit is powered by a high-torque 3 kW Gearmotor (Reducer), providing consistent pulling power to remove cattle hides smoothly. The machine features a Hot-Dip Galvanized Bodyfor superior structural strength and corrosion resistance, coupled with a Custom-Engineered Drum system to ensure efficient wrapping and separation of the hide.

Powerful Drive System: Equipped with a 3 kW Heavy-Duty Gearmotor that delivers unstoppable torque for dehiding even large animals.

Calibrated Chain System: Utilizes 8mm or 10mm Calibrated Stainless Steel Chains (depending on preference) for safe and slip-free operation.

Custom Drum Design: Features a specially manufactured drum for smooth hide winding, preventing damage to the leather.

Reinforced Chassis: Built with a Hot-Dip Galvanized Body, offering a "Strong Body" structure that withstands heavy mechanical stress.

Mechanical Simplicity: No hydraulic leaks or complex maintenance; just pure mechanical power and durability.

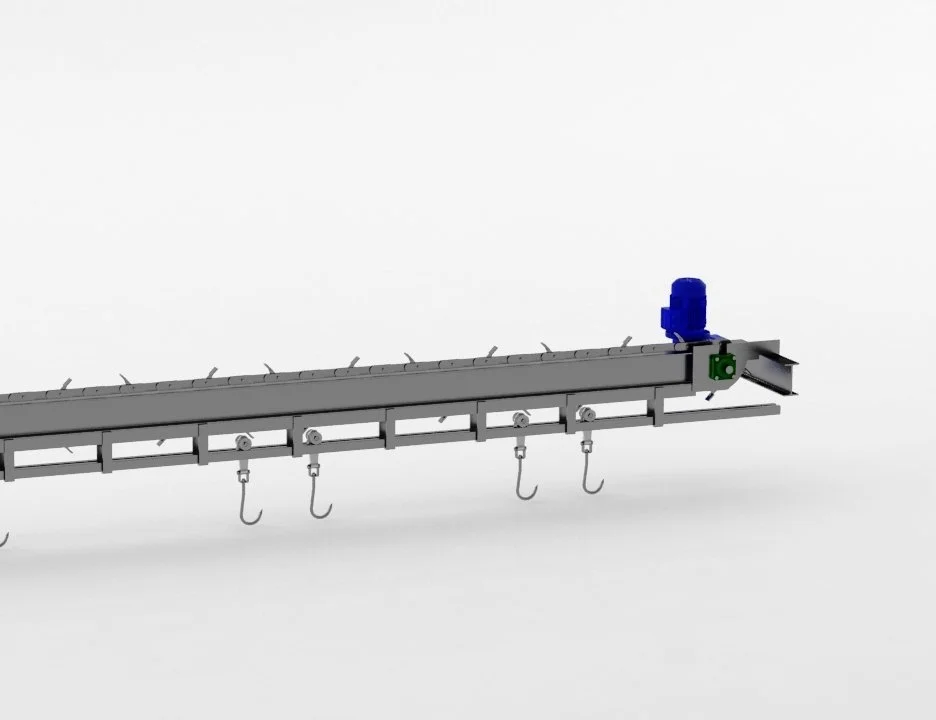

Hygienic Stainless Steel Carcass Transport Systems for Modern Abattoirs

Maximize your facility's workflow with Teknotes Group's advanced Overhead Rail Systems. Engineered from heavy-duty AISI 304 Stainless Steel profiles and pipes, our Twinrail and Monorail conveyors ensure the smooth, hygienic, and safe transport of cattle and sheep carcasses.

Unlike standard rails, our systems are designed for high load capacity and friction-free movement, preventing contamination and ensuring full compliance with international food safety and hygiene standards.

Overhead Rail Systems:

Twinrail & Monorail Conveyors

Cattle Overhead Conveyor & Rail System

Heavy-Duty Monorail & Twinrail Lines for Beef Processing

The Teknotes Cattle Overhead Conveyor is the backbone of high-capacity beef abattoirs, engineered to transport heavy carcasses (up to 1,500 kg) smoothly through the bleeding, dressing, and cooling stages.

Manufactured entirely from AISI 304 Stainless Steel, this robust transport system is available in both Twinrail (for high automation) and Monorail configurations. It features a synchronized drive system that minimizes manual handling, ensuring a continuous workflow while maintaining strict hygiene and occupational safety standards."

Double Safety Tensioner: Equipped with an advanced Safety Tensioning Station that automatically stops the system in case of jamming, preventing chain breakage and accidents.

Heavy-Duty Chains: Features custom-manufactured, high-tensile Stainless Steel Chains designed specifically for the project’s load requirements.

Direct Drive Transmission: Powered by high-torque Gearmotors directly coupled to the shaft for reliable, slip-free power transmission.

Versatile Rail Options: Compatible with both Tube Rail (Monorail) and Flat Bar (Twinrail) systems, integrating seamlessly into existing or new facilities.

Hygienic Design: Open-structure design prevents dirt accumulation and allows for easy high-pressure cleaning.

Butcher Working Platforms

Hydraulic, Pneumatic, and Fixed Stainless Steel Platforms for Slaughterhouses

The Teknotes Butcher Working Platforms are designed to provide ergonomic, safe, and hygienic working conditions for operators in slaughterhouse and meat processing facilities.

Available in hydraulic, pneumatic, and fixed platform types, these units ensure precise height adjustment, operator stability, and easy cleaning during cutting and processing operations.

Technical Specifications:

Dimensions: 800 × 1000 mm

Coating: 3 mm thick composite surface

Edge Parapet: Ø32 pipe safety railing

Working Height Range: 500 mm – 1700 mm

Load Capacity: Minimum 200 kg

Motion: Pneumatic pistons for vertical movement

Equipped with control panel and bottom–up limit switches

Material: Full stainless steel construction

Floor: Red anti-slip composite surface for safety and hygiene

Built entirely from stainless steel, these platforms meet international hygiene and safety standards, making them ideal for modern slaughterhouses and meat processing lines.